- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- 简体中文

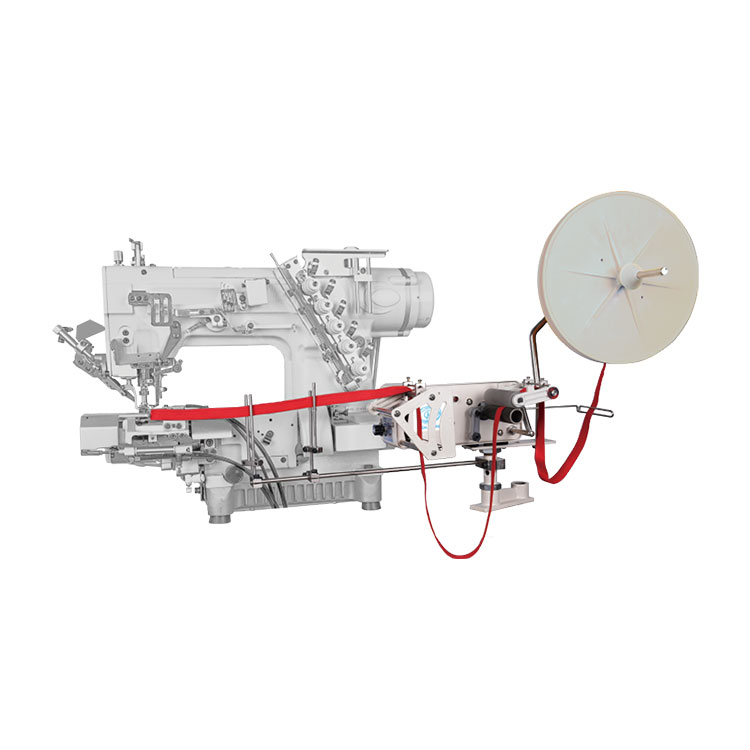

Side Tape Feeder

Welcome all new and old customers to visit HD factory and purchase our high-quality side tape feeder. As a professional manufacturer, we bring you cost-effective products at affordable prices. We look forward to every cooperation with you to start a convenient and efficient production journey together.

Send Inquiry

The use of side tape feeder is indeed a complex and demanding operation, and each link is closely connected and indispensable. This process not only tests the professional skills of the operator, but also reflects the ultimate pursuit of details and precise control of the production process. The precise execution of each step is the key to ensure smooth production and high product quality. From equipment inspection to parameter adjustment, to precise placement of raw materials and real-time monitoring of equipment, each step is like a precise gear, jointly promoting the harmonious operation of the entire production line:

Before using the side tape feeder, the operator is responsible for a comprehensive inspection of the equipment, which is the first checkpoint to ensure smooth production. They need to check whether the rollers show signs of wear, whether the side seam device is accurately aligned, whether the hopper is firmly fixed, and whether other key components are intact. This series of inspections is intended to lay a solid foundation for the subsequent production.

Next, according to the specific needs of production, the operator carefully adjusts the various parameters of the side tape feeder, such as feeding speed, side seam width, feeding tension, etc. The purpose of these adjustments is to ensure that the material can accurately meet the process requirements during the feeding process, thereby ensuring the quality of the final product. The fine-tuning of each parameter is a fine control of the production process.

After the equipment is started, the side tape feeder is put into operation. At this time, the operators remain highly alert and closely monitor the operating status of the equipment. They pay attention to whether the feeding is smooth, whether the side seams are uniform, and whether there are signs of abnormal noise. This real-time monitoring becomes the key to ensuring a smooth and error-free production process, ensuring that any potential problems can be discovered and resolved in a timely manner.

Features:

Lower costs: Although the initial investment may be high, in the long run, side tape feeder helps reduce overall production costs by improving production efficiency, reducing waste and labor costs.

Improve production efficiency: side tape feeder can feed materials continuously and stably, reducing downtime in the production process, thereby improving production efficiency.

Precise control: By accurately adjusting parameters such as feeding speed, side seam width and feeding tension, side tape feeder can ensure that materials are fed out in precise sizes and shapes, reducing waste and improving material utilization.

Improve product quality: Since side tape feeder can accurately control the feeding of materials, it helps to produce products with consistent quality and reduce product quality problems caused by inconsistent material sizes.

Reduce manual operations: side tape feeder with a high degree of automation can significantly reduce manual operations, reduce labor intensity, and reduce human errors.

Strong adaptability: side tape feeder is suitable for a variety of materials and products, and can adapt to different production needs and environments, with high flexibility.

Space saving: Compared with traditional feeding methods, side tape feeder is more compact and can save space in the production workshop.